There are many sources on the Internet that provide guides to door hardware finishes with brief descriptions. In this article I describe the most common finishes in more detail to try to make it easier for hardware specifiers and installers to identify finishes in the field.

The ‘finish’ of a piece of door hardware refers to its color and the degree to which it reflects light. These qualities are defined (more or less) by alphanumeric codes called ‘finish codes.’ I say ‘more or less’ because often there are noticeable differences in finish between pieces of hardware by different manufacturers and sometimes between pieces manufactured in the same factory at the same time. This is especially true of “living” finishes – that is, finishes that are designed to age naturally over time – such as US10B, oil rubbed bronze. More about that later.

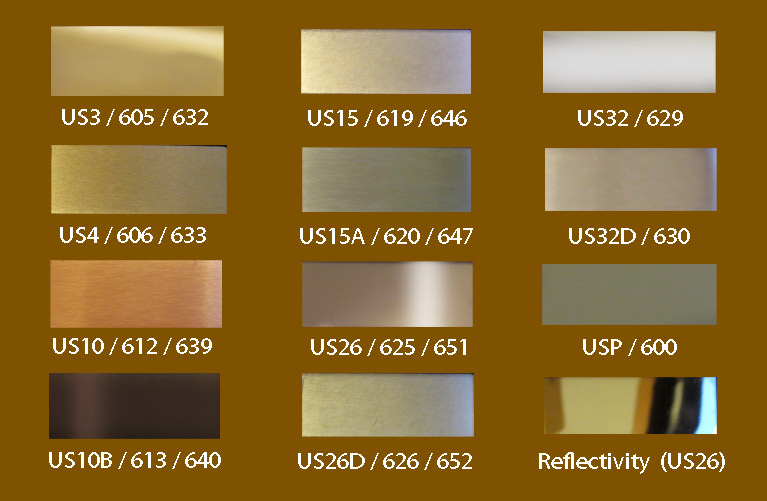

In the United States there are two finish code systems: U.S. finishes, created by ANSI (American National Standards Institute) and BHMA finish codes (Builders Hardware Manufacturers Association). U.S. finishes describe only the color whereas BHMA finish codes describe both color and base material. The most notable exceptions to this rule are US32, polished stainless steel, and US32D, satin stainless steel. These U.S. finishes describe both the finish and the base material. The corresponding BHMA finish codes would be 629 for polished stainless and 630 for satin.

BHMA finish codes are different for different base metals. For example, BHMA 626 is satin chrome plated brass whereas BHMA 652 is satin chrome plated steel. Base metal can be important when choosing hinges for interior vs. exterior use. BHMA 632 (polished brass plated steel) finished hinges will rust whereas BHMA 605 (polished solid brass) finished hinges will not. Hinges in 632 finish are much less expensive than those in 605 finish, and it is absolutely fine to use them in dry interior environments.

A “polished” (or “bright”) finish is one that has been buffed until it reflects like a mirror. If you can see your reflection clearly in your doorknob or kick plate, for example, it is safe to say that it is a polished finish. I have included a raw photograph of a polished finish in the lower right hand corner of the photo below.

The opposite of a polished finish is a satin finish. You cannot see your reflection in a piece of hardware with a satin finish without quite a bit of imagination.

Below is a chart showing the most common finishes with their U.S. and BHMA finish codes:

Notice there are several finishes that might be described as slightly luminous shades of gray. Right here is where the most trouble is with finishes. In particular there are US15 (BHMA 619 or 646) satin nickel plated, US15A (BHMA 620 or 647) antique nickel plated, US26D (BHMA 626 or 652) satin chrome and US32D (BHMA 630) satin stainless steel. There are subtle differences between them. Of these four, US26D is the lightest shade of gray whereas US15A is the darkest. In between are US15 and US32D, and between these two US32D is just slightly darker. To the untrained (or uncaring) eye these four finishes may appear exactly the same, but all it takes is the installation of an antique nickel lever on a door right next to another door that has a satin nickel lever on it to earn somebody an expensive paperweight.

The other finishes are much more easily distinguishable:

- US9 (BHMA 611 or 637) bright bronze (not shown above) is not a very common finish, but easy to identify. It’s like a copper penny where the Lincoln’s face has been buffed clean off, and now you can clearly see your face instead his reflected in the penny.

- US10 (BHMA 612 or 639) satin bronze is a copper color, like a new penny, buffed to a satin finish, does not reflect images clearly.

- US10A (BHMA 616 or 643) brown with a little red in it. Not commonly used in locks, but common in hinges. Not reflective. A “living” finish.

- US10B (BHMA 613 or 640) plain brown, not reflective. A “living” finish.

- US26 (BHMA 625 or 651) polished (or bright) chrome. Silver in color, you can see yourself clearly reflected.

- US3 (BHMA 605 or 632) polished (or bright) brass. Gold in color, you can see yourself clearly reflected.

- US4 (BHMA 606 or 633) satin brass. The same yellow gold color as polished brass, but does not reflect images clearly.

- US5 (BHMA 609) antique brass. Same as satin brass except with black accents.

- US32 (BHMA 629) polished stainless steel. This mirror finish is similar to US26 above, but just slightly darker. As with satin chrome and satin stainless, it can be difficult to distinguish between polished chrome and polished stainless. If it is an exterior application or a corrosive environment it is probably stainless.

- USP (BHMA 600) prime coat over steel. Hinge has been painted with gray primer and is ready to paint.

Using a Camera to Identify Door Hardware Finishes

As you can see by my photo of a manufacturer’s sample of US26 bright chrome at right (and in the photo above), it is very hard to tell  what the finish is by looking at this photo. This is because it has a mirror-like finish that reflects back all the colors that are in the room. Yet actually most finishes have a degree of reflectivity that will show up in photos. All in all it is a lot easier to identify the finish yourself on the job while looking at finish samples than to send a photo of the item to, for example, your hardware dealer for identification. Most established door hardware manufacturers have brochures that accurate depict an assortment of finishes. Using their pictures to identify the finish is like having access to their professional photographer. Why would you try to use your phone camera when there is a professional photographer at your disposal?

what the finish is by looking at this photo. This is because it has a mirror-like finish that reflects back all the colors that are in the room. Yet actually most finishes have a degree of reflectivity that will show up in photos. All in all it is a lot easier to identify the finish yourself on the job while looking at finish samples than to send a photo of the item to, for example, your hardware dealer for identification. Most established door hardware manufacturers have brochures that accurate depict an assortment of finishes. Using their pictures to identify the finish is like having access to their professional photographer. Why would you try to use your phone camera when there is a professional photographer at your disposal?

About “Living” Finishes

Living finishes are finishes that are designed to age naturally over time, such as US10B, oil rubbed bronze. The oil rubbed bronze finish seems to come out of every factory a little differently each time. Often on a large job done in US10B finish you will find that all of the hardware is, in fact, the same finish, yet it is all slightly different in color. This is not usually avoidable. Also individual hardware items with living finishes will age differently over time depending on use and slight differences in how the finish was applied at the factory. US10B hardware that has been around a while may end up looking like bright bronze, satin bronze, satin brass or antique brass.