Preparedness for the Commercial Door Hardware Installer

One of the most time consuming aspects of hardware installation is travel to and from the job. In a perfect world, the installer knows in advance everything they will need, but as we all know, the World of Hardware is not a perfect one. Often there is no opportunity to survey the job beforehand and the information given by the client is often either sketchy or nonexistent. As a result, travel time to and from is often doubled or tripled by the necessity to ‘go back to the shop’ to pick up the parts needed to complete a given job. A certain amount of travel time is billable, nevertheless your customer is not happy paying for it, trust me.

While it is virtually impossible for a hardware or access control installer to be always prepared for every need, here are some items that go a long way toward helping to reduce travel time that results from a lack of parts.

Generally Speaking

The first rule of hardware preparedness is to pay attention. What kind of hardware does your customer have, and what do they have that tends to break? If your customer has a building full of mortise locks will swivel spindles, best keep a few of those spindles on the truck because you know they are going to break in the middle. If your customer has entrances with Doromatic 1690 or 1990 concealed vertical rod devices, you’d better stock a few pinion cams because you know the teeth are going to break off of them. Whenever you repair anything that looks like it’s poorly made and notice there is a quantity of it on the property, best carry what you need to fix it.

If you are doing a lot of work for a client and they have a particular kind of lock, be sure to stock a few. The property manager will be impressed when you triumphantly produce one from your service vehicle in the nick of time.

Fasteners

You know what fasteners you often find missing in action. Undercut flat Philips head 12-24 1/2-inch self tapping hinge screws, for example. In an emergency they can double as ANSI strike screws. Collect those 6-32 3/4-inch combination machine/wood screws from tubular and cylindrical lock latch and bolt fronts. They can double as screws for a mortise lock armor front if you cut them short. For aluminum doors it can be very handy to carry some 10-32 x 2-inch flat head Philips machine screws, and its always good to have a few universal mounting tabs around just in case.

Other Stuff

On the electrical side it’s always good to have a SPDT relay, one each of a 12vdc and 24vdc 1-Amp plug-in power supply and a 4-1/2 x 4-1/2 4-wire electric power transfer hinge in satin chrome are all things that one tends to find oneself wishing for on the job; the Securitron TM-9 timer module sure does come in handy sometimes; on the lock frontier it’s always good to have a few cheap replacement cylinders for emergencies; and a full surface reinforcing pivot hinge can be a life saver sometimes, though because they are handed you do have to carry both hands for the full prophylactic effect.

In addition to these common sense items there are a couple of products that can save a parts run, too.

LCN 4040XP

The 4040XP in the RW/PA configuration (by the LCN Door Closer division of Ingersoll Rand) is a non-handed door closer like many others that can be installed in either regular, top jamb or parallel arm mount. Its adjustable spring tension makes it a perfect choice for doors that require a lot of force to close due to wind or other conditions, or for an ADA compliant opening that must open with minimal resistance. If the installer carries the closer and the 4040-18, 4040-18PA and 4040-18TJ drop plates, they will be able to install the 4040XP on almost any door. The most popular finish of the 4040XP is 689 aluminum.

HES Electric Strikes with Faceplate Options

Hanchett Entry Systems (HES) has greatly advanced the concept of the modular electric strike since the company was founded.

- The HES 1006 is field selectable for 12 or 24 volts DC power input, and with an optional Smart Pac line conditioner you can use anything from 12 to 32 volts AC or DC. A variety of available faceplates for the 1006 enable the strike to accommodate virtually any lock. Carrying a 1006 body with one each J option, K option, KD option and KM option faceplates and one Smart Pac will allow the installer to fill the need for an electric strike for 95% of all storeroom function cylindrical and mortise locks where the installation involves a hollow metal frame.

- The HES 5200 is field selectable for 12 or 24 volts DC power input and any power input from 12 to 32 volts AC or DC with a Smart Pac. Unlike the 1006, the 5200 is field selectable for fail safe or fail secure. Since the 5200 has a three quarter inch keeper depth it will accommodate a mortise lock in a pinch, but really the 5200 is for use with cylindrical locks in hollow metal, wood or aluminum frame applications or for aluminum storefront door applications that include the Adams Rite deadlatch. I recommend installers carry one each of the 501, 502 and 503 faceplate options to be prepared for the majority of these installations.

There are many things I’m sure I’ve missed: electrical tape, fifty feet of 18/2 non-shielded wire, really sharp wood chisels, batteries – all kinds of stuff. But don’t worry. You’ll know what it is the next time you have to drive back to the shop to get it.

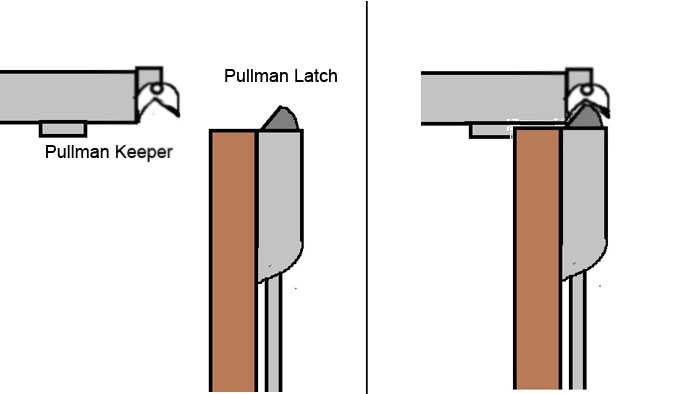

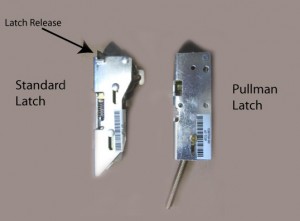

A Pullman latch is a type of exit device latch. The leading edge of a Pullman latch, the part that hits the strike first as the door closes, is a ramp. The back of the latch, the part that rests against the strike to keep the door latched shut, is rounded. When the Pullman latch comes into contact with another object it retracts automatically. It is a simple, spring-loaded mechanism.

A Pullman latch is a type of exit device latch. The leading edge of a Pullman latch, the part that hits the strike first as the door closes, is a ramp. The back of the latch, the part that rests against the strike to keep the door latched shut, is rounded. When the Pullman latch comes into contact with another object it retracts automatically. It is a simple, spring-loaded mechanism.