I was taking a class on Molex connectors a while ago and the teacher – a manufacturer’s representative from a major hardware manufacturer – expressed the opinion that for high traffic applications, a power transfer is preferable to an electric thru wire hinge. I confess that until that moment I had not actually thought about it much, but what he said made a lot of sense. After all, almost everyone prefers an electric hinge to an EPT because of the relative ease of installation.

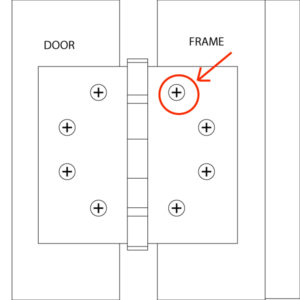

But the rep made a good point. The wires that run through an electric through an electric hinge are pretty thin – usually 24 or 26 gauge wire – and every time the door is used these wires are bent back and forth. If you’ve ever bent a copper wire back and forth in your hands until it breaks you will know what I’m getting at here. When you bend a copper wire back and forth, over and over, first it heats up, then it breaks. The same process is going on in the knuckle of that hinge. There’s a whole lot o’ twistin’ goin’ on.

When you open a door equipped with an EPT, however, there is less twisting happening. The wires must still bend with the motion, but only a fraction of the bending that occurs with an electric hinge. That’s why the rep always recommends EPT’s over electric hinges if the opening is to have any serious traffic through it. Sure, installing an EPT is a lot more work, but a callback to replace a failed electric hinge is at least as much work, especially considering travel time.

Yes, you’re right, I did mention Molex connector class. A few times now I’ve run into applications where the installer wants to convert a regular removable mullion into an electric mullion so they can install an electric strike on the mullion. Since the advent of the surface mounted electric strike for rim exit devices, it was inevitable that someone would want to do this. The problem? What do you do with the wire at the header? Well, if you just run a continuous wire, the mullion is no longer removable, is it?

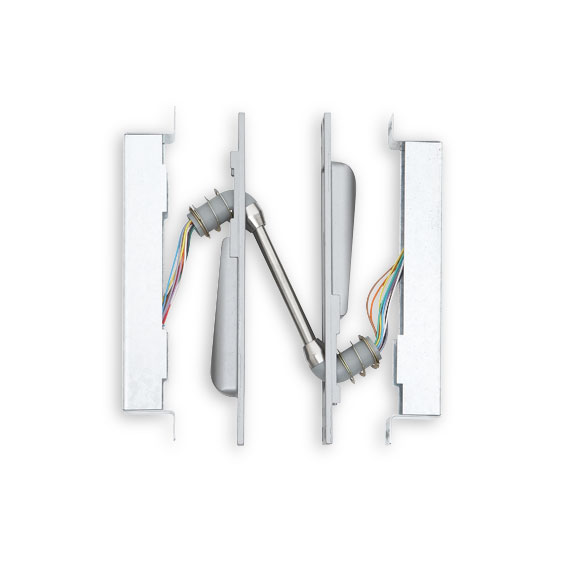

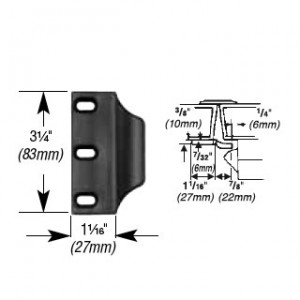

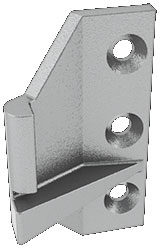

But, aha! I said. We’ll use a Molex connector at the header. What is a Molex connector, you ask? Those would be those plastic connectors attached to the ends of the wires on the McKinney hinge above. Molex is a company that has created a system of plug-and-play wire connectors, and these connectors are becoming more and more common in the door hardware industry. Major door hardware manufacturers are now incorporating Molex connectors into all their electrified products and offering what are in effect extension cords with Molex connectors.

So a couple of connector-equipped extension cords would solve the problem of the suddenly non-removable mullion, right? Well, not so fast, buckaroo.

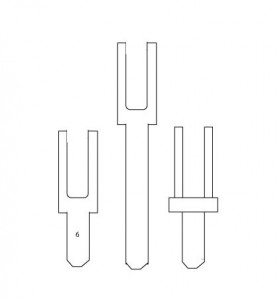

This is what I learned in Molex class. In Molex connectors, which connector will connect to what other connector is determined by the pin crimped onto the end of the wire. They give them genders, “male” and “female”, because the male can be inserted into the female. Okay, great. Where is the problem? The problem is that as of this writing, door hardware manufacturers’ extension cords all have connectors of the same gender on each end, so you cannot plug them into each other. They will only plug into an electric hinge or EPT that has Molex connectors.

The solution to the DIY electrified mullion problem: make your own DIY Molex connector for the wire in the header. To do this you will need a standard wire stripper, some 12-conductor cable, the special Molex crimping tool, Molex connector housings, and Molex male and female pins. There is a service kit available that contains all these parts. It is a fairly time consuming process to make your own Molex connector, and it requires skill, but it is the only solution that I know to the mullion problem.

Get your surface mount electric strike with Molex connectors (several electric strike manufacturers offer these) and an extension cable from Assa Abloy or Allegion to get the wire from the strike to the top of the mullion. Now you have the capability to connect your makeshift electrified mullion into the connector you must make. You can attach your homemade Molex to as long a cable as you like – long enough to reach the power supply or access control panel.

Does this solution comply with code? I do not know. Best check with your local AHJ before embarking on your Molex DIY mullion adventure.

Why is the industry moving to Molex connectors? They do not fall off, look ugly, or take up a lot of space like wire nuts, and if you need to trade out an electric hinge or electric strike they sure do make it a whole lot cleaner and easier.

That’s right. As usual, it all comes down to sex.

Your source for quality security products with superior service!